Liquids

Focus Areas

Test Stand

We are responsible for the design, assembly, and validation of the Diablo test stand. This stand will facilitate ground testing of our next generation of liquid engines. Our team brings together the tanks, valves, and instrumentation required to deliver fuel and oxygen to our engines. We also develop the custom DAQ system and control software necessary to conduct and analyze tests. Our goal is to enable and maintain a rapid testing cadence for liquid engines for years to come.

Propulsion

We develop the engines that power SRL liquids. This team designs and manufactures injectors, nozzles, and combustion chambers for all liquid engine projects. Over the past year we have completed multiple static fires and gained a wealth of valuable data and experience with liquid propulsion. We are taking this experience forward into designing more advanced, performant engines.

Flight Vehicle

As SRL liquid’s newest team, we work closely with the propulsion development team to take the results from their tests and integrate them into a flight configuration. We design and manufacture airframes, tanks, and recovery systems to be used with our engines. Our long term goal is to create a vehicle for entry into FAR’s dollar per foot challenge.

Current Projects

Diablo

SRL Liquids has identified liquid oxygen (LOX) as the clear path forward in our development. In order to prepare for our first flight vehicle we are prototyping two engines in parallel, for use with one test stand. Working with multiple industry mentors, our goal is to rigorously test these engines before integrating them into flight vehicles.

Objectives:

Characterize our two engines

Develop robust procedures for the operation of LOX-powered engines

Create a path forwards to a liquid fueled launch vehicle

Create a test stand that can facilitate future liquid engine development

Diablo supports up to 2000 lbf thrust, 23.5 gallons of fuel and 27.5 gallons of oxidizer.

Taipan Rocket Engine

Taipan is a bipropellant liquid rocket engine fueled by nitrous oxide and ethanol. Designed, built, and tested entirely in-house, it will produce 650 lbf of thrust using a bang-bang pressurization system, unlike impinging injector, and ablative cooling for thermal protection.

Specifications:

• Thrust: 650 lbf

• Chamber Pressure: 700 psi

• Chamber Temperature: 5000°F

• Injector Type: Unlike Impinging

• Thermal Protection: Ablative

• Engine Diameter: 3 in

After validating our propulsion system with nitrous oxide and ethanol, Taipan will undergo iterative upgrades toward operation with liquid oxygen and kerosene. The final goal is integration into a flight vehicle to compete in the FAR Dollar-per-Foot Challenge.

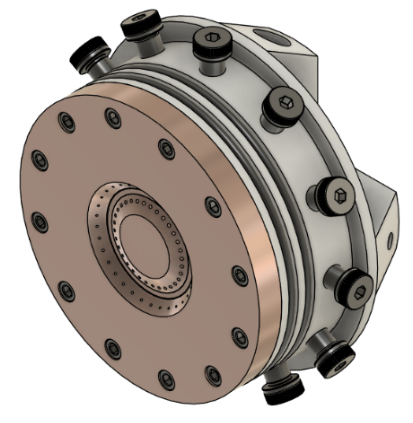

Scorpion Rocket Engine:

Scorpion is a bipropellant liquid rocket engine. It utilizes a kerosene and liquid oxygen propellant combination and features an unlike impinging-jet injector, an ablative thermal protection system, and a modular two-part nozzle. All components are designed, manufactured, tested, and analyzed in-house by CU SRL students.

Specifications:

Thrust: 1,200 lbf

Chamber Pressure: 700 psi

Chamber Temperature: 5,894 °F

Injector Type: Unlike impinging-jet

Thermal Protection: Ablative

Diameter: 5.5 in

The Scorpion program aims to complete a series of static fire tests during the 2025–2026 academic year to validate performance and inform iterative design improvements. Following successful ground testing, the team plans to integrate Scorpion into a flight vehicle to compete in the FAR Dollar-per-Foot Challenge.