Manufacturing

Manufacturing Team Overview

Need a part made? Need it fast? Need high tolerances? Then you’ve come to the right place! Manufacturing is the bridge that connects our raw ideas, designs, and drawings into the practical finished parts that make up our rockets. If you like being close to the action and don’t mind getting your hands a bit dirty, then this is the team for you! From machining raw metals to winding composites, the SRL Manufacturing Team strives to deliver high quality parts for any use case while adhering to proven safety and quality standards. Read on to learn learn more about our manufacturing capabilities!

Composites Manufacturing

From custom phenolics to the first and largest student-built fully composite solid rocket motors, composites are the backbone of SRL’s technologies. Tremendous R&D effort has gone into scaling manufacturing while refining part quality for any project we take on.

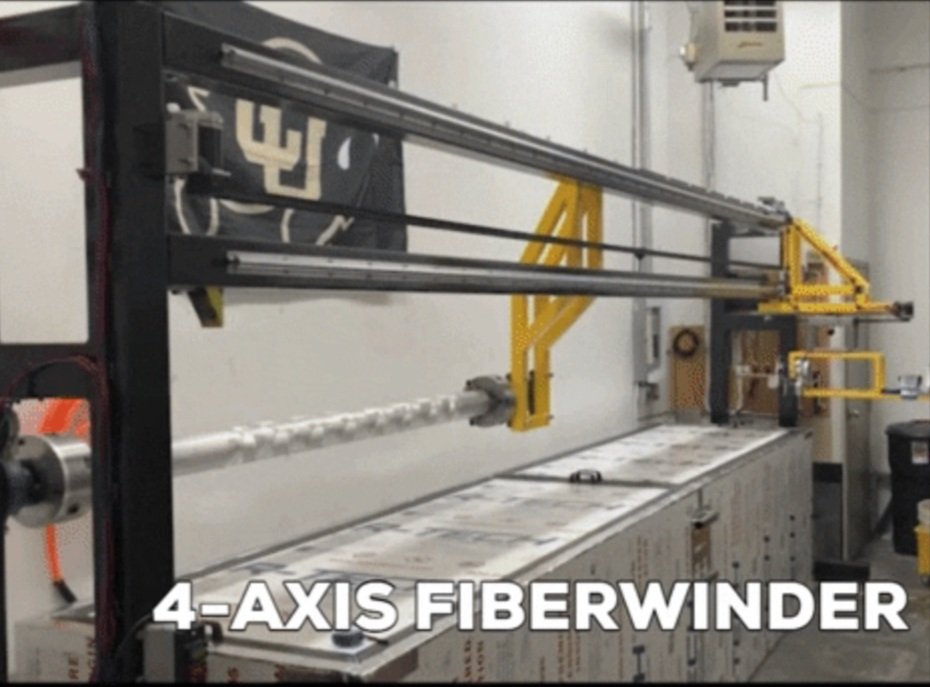

4-axis Fiberwinder: This is the machine that makes the machine. Designed in-house, it was reverse engineered from our previous 2-axis commercial winder. Starting from scratch gave us the opportunity to create a system capable of evolving in a rapid feedback loop with our vehicle and propulsion technology. It is responsible for producing 18” diameter airframe sections up to 15′ long, R-class solid rocket motors, composite overwrapped pressure vessels (COPVs), and liquid engine nozzles

Machining

From manual lathe control to CNC milling, the precision and adaptability of machining cannot be understated. Machining not only allows us to create parts with thousandth-of-an-inch precision but also enables us to work with a wide range of materials, from steel to graphite. This versatility empowers us to adapt and innovate, meeting the unique demands of each mission we undertake. Taking advantage of on-campus machine shops we’ve made anything from thrust chambers to pintle injectors; the possibilities are endless.